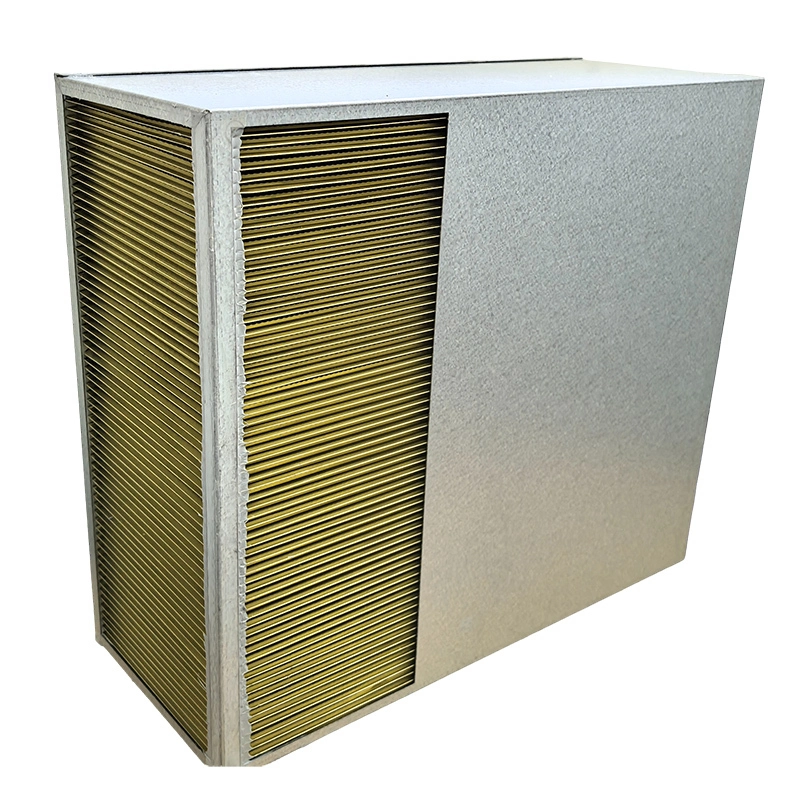

Quick Heat Exchanger Core Air-to-Air Energy Conservation Corrosion Resistance

The heat exchange core is a central component in ventilation systems, responsible for efficiently transferring heat and humidity between different air streams to achieve energy conservation while preventing air mixing.

Material Selection:

The heat exchange core surface is uncoated, made of aluminum-zinc coated plate without restrictions on patterns, ensuring the material's corrosion resistance and durability. The fins are made of golden hydrophilic aluminum foil, with specifications that can be customized to optimize heat transfer efficiency.

Product Design Feature

Manufacturing Process:

The gluing process is strictly required to ensure a solid connection between the fins and the heat exchange core. The shell body's connecting lugs need to be precisely pressed to ensure structural stability. The fin angle at the air outlet is controlled within 15 degrees, with even spacing, no deformation or damage, and maintained cleanliness.

Quality Control:

The use of silicone is strictly controlled, not to exceed the outer surface of the shell, allowing a small amount of residual glue that does not affect assembly. The product has passed the IEC68-2-52 standard's severe level 2 alternating salt spray test, with no corrosion on the fins after 10 cycles, proving its excellent corrosion resistance.

Size Accuracy:

The hole position tolerance is ±0.2mm, the outer dimension tolerance is ±0.5mm, and other sizes follow the GB/T1804-m standard, ensuring the precision and consistency of the product.

Environmental Protection and Safety:

The heat exchange core has a protection level of IP55, adapting to harsh environments and preventing dust and water intrusion. It complies with the ROHS standard, restricting the use of harmful substances, protecting the environment and health.

Technical Innovation:

The sensible heat exchange core uses hydrophilic coated aluminum foil to quickly transfer heat and minimize environmental impact. The modular structure and design without moving parts make the heat exchanger compact, customizable, and low maintenance. The spiral wave heat transfer enhancement technology increases the heat transfer area and efficiency, ensuring strength and sealing under high pressure.

Wide Application:

Suitable for residential, commercial, and industrial applications, including HVAC and wind power industries, demonstrating technological innovation in energy conservation and air quality management.

Product parameter

| Model | Spec (L*W) (mm) | Plate Distance (mm) |

| 250/250 | 250 X 250 | 2.2 |

| 315/315 | 315 X 315 | 2.5 |

| 400/95 | 400 X 95 | 4 |

| 400/200 | 400 X 200 | 2.2 |

| 460/190 | 460 X 190 | 3 |

| 450/140 | 450 X 140 | 4 |

| 600/235 | 600 X 235 | 4.5 |